Plate Heat Exchanger Gaskets

Product Details:

Plate Heat Exchanger Gaskets Price And Quantity

- 790 INR

- 25 Set

Plate Heat Exchanger Gaskets Trade Information

- 300 Set Per Day

- 2-3 Week

- Contact us for information regarding our sample policy

- All India

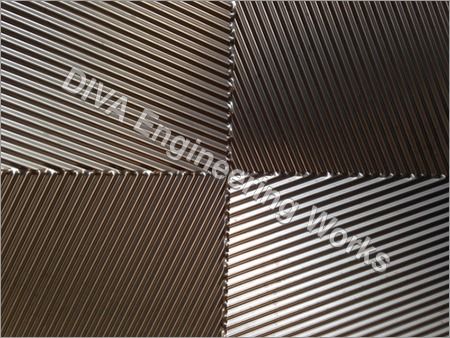

Product Description

The Gasket Plate Heat Exchangers are the main part of the heat management system. The product is designed in various capacities to meet the diverse requirements of clients. The product is used in various industries for heat management like chemical, food processing, mechanical, etc. The product is made as per the set industry standards to ensure quality and reliability. The Gasket Plate Heat Exchangers are available at a very reasonable price.

Main Features:

- Easy and quick installation

- Durable and high endurance

- Less repair and maintenance

The Complete Heat Transfer Equipment Gasket Set are available in the following Materials :

Wide range of Model HT plates & Gaskets are available with us some of them are as : Alfa Laval, APV- SPX, Swep Inernational, Bell & Gossett, Tranter, GEA- Ecoflex, HISAKA, Cummins, VICARB, Volvo-Penta, Meuller, CETETHERM, B&W Man, DEUTZ-MWM, Sondex, SCHMIDT-BRETTEN, Meuller, Reheat, HISAKA, CATERPILLAR, VITHERM etc.

| Material | Max. Temperature ( in Deg. C. ) |

| NBR Standard ( Nitrile / Perbunan ) | 110oC |

| NBR - HT( Peroxide - vern. ) | 130oC |

| HNBR( Hydrogen ) | 160 - 165oC |

| EPDM | 150 - 155oC |

| EPDM- HT ( Peroxide vern. ) | 160 - 165oC |

| FPM - B ( Flauorelastomeer ) | 180oC |

| FPM- G ( Flauorelastomeer ) | 220oC |

| VITON or Special Gasket | |

How to Select Gasket :

- Choose your Heat Transfer Equipment Model / Description

- Select the application

- Industrial or Food, Chemical or if any

- Types of Gasket -Glue or Clip on

- Note the number of gaskets, port rings etc.

- Contact DIVA Office - Dealer - Supplier

Also, You can send your heat exchanger or plate pack to our workshop, We make sure that it is professionally overhauled and returned to your premises.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Heat Exchanger Spares Parts' category

|

DIVA ENGINEERING WORK

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |